1960 -1969

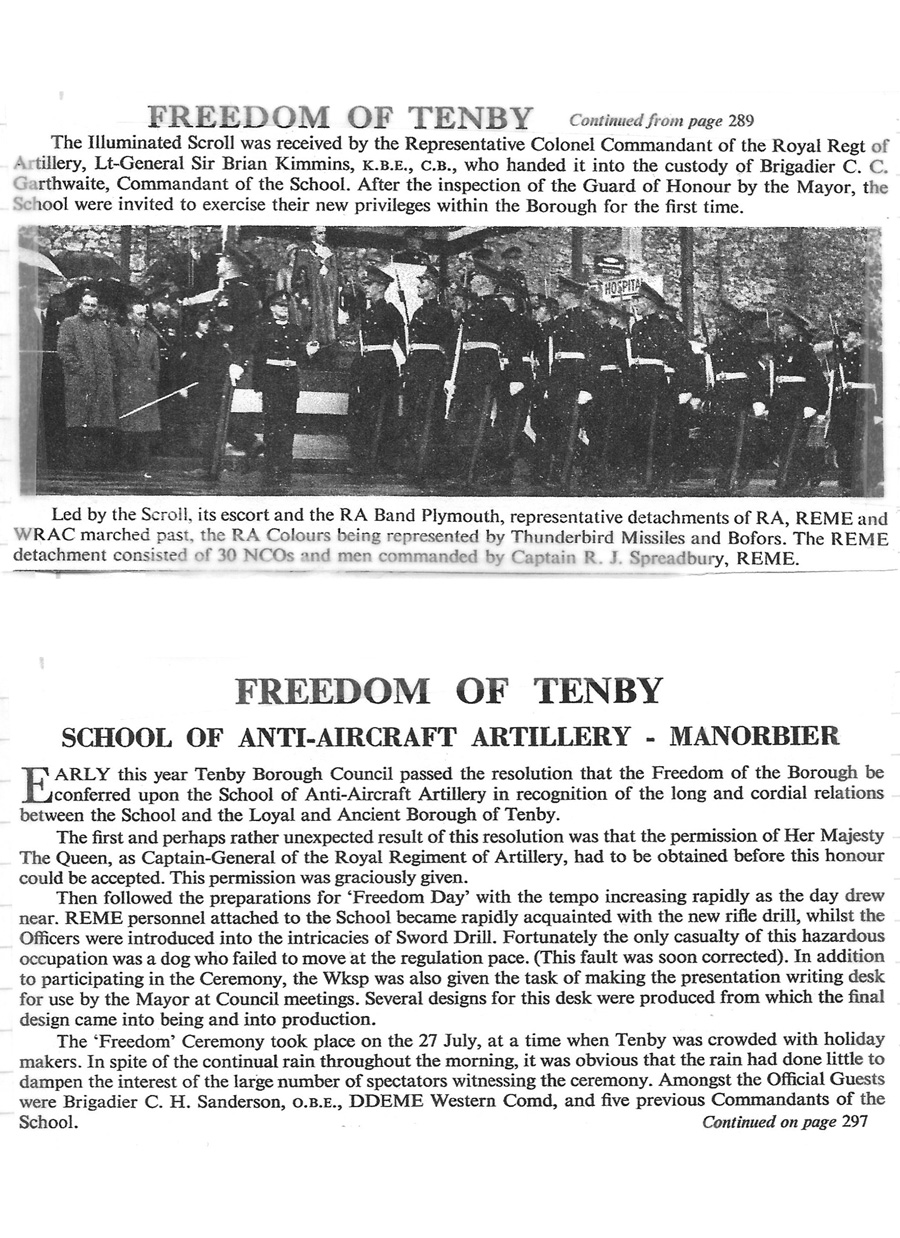

While at the School of Anti-Aircraft Artillery at Manorbier, the only outstanding thing that comes to mind was when the school was given the Freedom of Tenby, a resort town a few miles up the coast from the school. It was decided that July 1960, the school would exercise it’s might to march through Tenby with bayonets fixed and the band playing. My O.C., a major should have led the R.E.M.E detachment, but he had been stricken with a kidney stone and was in agony. Anyway, I got the job, borrowed a sword from a major at the school who gave me a quick lesson in sword drill (it is not a requirement in officers’ school). There we were, two hours before the parade formed in columns, in our best dress blues in the pouring rain. We were all soaked through and I recall watching the rust form on the sword blade as it rested on my shoulder.

By this time, I had concluded that I had no future in the army. I was on what was called a “short Service Commission”. With this form of commission, one re-engages for three years at a time. As I already had 14 years of service, (from Oct 1946 to Oct 1960) I questioned whether I could get to 22 years (required for pension) but could get no satisfaction. What I did find was that if I waited to 1962, the next time I could re-enlist they were refusing to extend short service commissioned if there was a likelihood of you qualifying for a pension.

So, at this time, I decided I had had enough and I applied for a discharge, preferring to take my chances out of uniform.

The army did provide a three-month paid period if you could find a company that would take you on as a trainee. So, before I left I sent out letters to several companies giving them my resume. I had two responses, one with English Electric just north of London and one from Associated Electrical Industries (A.E.I) in Trafford Park, Manchester.

I interviewed with both, was turned down by English Electric (to my delight, I didn’t like the atmosphere there) and got an offer from A.E.I as a trainee.

So, in Sept 1960 I went up to Manchester and started in the Servo and Defense Department, what a change that was. I initially helped with design of some servo amplifiers for the Navy. Transistors were just coming in then and the Navy was a little hesitant about their introduction. I knew nothing about them but had a crash course to get up to speed.

I was particularly impressed with the controlled rectifiers know as SCR’s and managed to get familiar with their characteristics and uses.

Anyway, after my three-month trainee experience, the manager of the department made me an offer as a design engineer at the princely salary of $1,100 per annum. I was tickled pink. In due course, we left Pembroke Dock and travelled up to Manchester where we found a suitable flat in Didsbury on the outskirts of Manchester. I was able to get a bus from there to central Manchester and then another out to Trafford Park.

The work was for the Navy primarily and I designed a power supply for the standard 21-inch torpedo and then a series of inverters (changing dc to ac). The largest was for an investor to drive a 100 hp ac motor which drove a pump which kept a liquid seal between the radio active cooling system and the outside cooling water. This was for Calder Hall Nuclear Station and the dc source was the 220v station battery.

The SCR’s we had then were made by A.E.I but were primitive by todays standards, they had to be selected for a short turn off time and were limited to 600v, not much margin for safety.

We had a number of failures in the field and it took some detective work to find out that the SCR’s which originally had a 600v capability were down to only 300v. It was finally determined that the equipment was located close to the reactor enclosure and the radiation strength there was irritating the SCR’s and reducing their voltage withstand.

Few other projects still come to mind. One came down from a company bigwig. The Shah of Iran wanted an inverter to operate from a 12v battery and run a small refrigeration on the Shah’s yacht.

The other was for the Army which had introduced a range of hand held power tools, including a rock hammer. Running off a 3 phase 400hz supply. Could we make an inverter to operate from a 24v battery. I built one and went down to the Military Experimental Establishment (M.E.X.E) in Christchurch, not far from my mother’s home, to test it.

They had a great lump of concrete available, I connected the inverter to the rock drill (hammer) and got it going. Most impressive, lumps of concrete going everywhere and a cloud of dust.

In 1964 I was called in and asked whether I would like to take the position of Section Engineering Manager at the Industrial Electronics Section at one of our sister companies in Leicester. The plant was known as New Parks and housed the radar group and the Industrial Electronics group.

The electronics group had a thriving business in the freighter ship industry. Most of these older ships still need 220v dc supply, obtained from a dc generator to supply all the power on the ship. With the advent of air conditioning, a number of relatively small commercial air conditioning units which were usually fed from 220v, 60hz.

The inverters were relatively simple units, using 4 SCR’s and were widely sold, as they merely chopped the 220v dc into 220v ac at 60hz.

Sales and marketing had, however observed a growing market in standby and no break ac supplies for electrical loads.

As the name implies, the standby units have an integrated rectifier and a battery, it’s supplied by the mains, with an inverter just sitting there. In the event of a main failure, a contactor connects the electrical load to the inverter, which operating from the battery, now supplies the load. There is a momentary break in the supply to the load.

The no break, as its name implies, has no break in supply to the load. There is still a rectifier, fed from the mains and a battery but the inverter feeds the load continuously.

Over the next three years, my three engineers and I designed and developed a range of standby and no break units up to 125hp rating.

At the end of 1967 our company was taken over (with the financial help of the government) by General Electric of Great Britain. It was a monumental disaster, G.E had been a competitor of A.E.I and had roughly the same range of equipment from big generators, motors, transformers, semiconductors, lamps and lighting to start with.

An aspiring manager managed to marry the managing director’s daughter. His name was Weinstock. He, apparently, convinced his father in law that selling off some of the G.E divisions, he could improve the cash flow.

Apparently, this worked, for a while, but when you have sold off some of your prime property, you have little left to sell.

Somehow, or another, he convinced the government that only the British electrical industry could complete with the US giants, G.E and Westinghouse, by combining G.E of Britain with English Electric, A.E.I and a few other smaller companies.

With the governments money the takeover was blessed, with, of course, G.E of Great Britain as the holding company. Anyway, in the dining hall for a presentation by a G.E representative. I can still hear him. As part of his speech he bellows “It’s people that cost money, do you get my message”, I certainly got the message.

A shot time later we were informed that A.E.I New Parks was going to be closed and that we’re going to be transferred to a sister division in Rugby. There would be no assistance in moving and Rugby was a major railway line to London and while only about 30 miles from Leicester, the bus service was nonexistent as it was, essentially, cross country.

I started looking for another job. At this time, one of my colleagues showed me a copy of the Times of London. Skimming through this I noticed an advert for engineers in the USA.

Nothing ventured, nothing gained, I applied to the advert address. A couple of weeks later, having come home late and was eating dinner when the phone rang and a American girls voice came on. ”Mr. Spreadbury” “yes” “Mr. Robert Spreadbury” “yes”, “this is Westinghouse Research Laboratories, Mr Walker, our Division Manager, will be in London in two weeks’ time, will you be available for a interview?” “yes”, then we were cut off. I had no number to call and wondered what happened.

I needn’t worry, a few days later I received a confirmatory letter giving me a time and place in London.

In due course I presented myself at his big London hotel room at the appointed time. I was made very welcome by Mr. A.H.B. Walker, Division Manager of the Electronics Technology Division of the Westinghouse Research and Development Center in Pittsburgh, Pennsylvania, USA.

It turned out to be the longest interview I had ever had. Two hours which included a written exam. During it we had a free ranging discussion on technology.

He seemed surprised that I had some knowledge of a magnetic simulation called a magnetic cross. Anyway, at the end of the interview he took my photo and said that he was not yet offering me a job, as he had interviews setup in France and Germany and some more in the UK, but if I did get an offer, it would be as a Senior Engineer at $16,000 per annum. I nearly fell through the floor. At the time I was making about £2000 a year.

He then told me that the Imperial Preference would be ending that year (when there was no limit to emigrants from the UK, all other nationalities had to fit in a quota).

He recommended that I go around to the US Embassy (just around the corner) and collect forms to immigrate to the US. “Fill them out and send them in”. I was not committed to that point and could always decline.

A couple of weeks later I received a written offer of employment at the level he had mentioned, together with the offer of free airplane tickets from London to Pittsburgh and free shipping of our household effects up to, if I remember 1000lb.

From then on, after I wrote to accept things everything went in to a blur. Confirm the emigration to the embassy. Notice to my company. Sell the house, no problem there, had two families fighting for it, the winner took our car (with a spare engine), a Wolseley, 1550 ex police car, my pride and joy, as well.

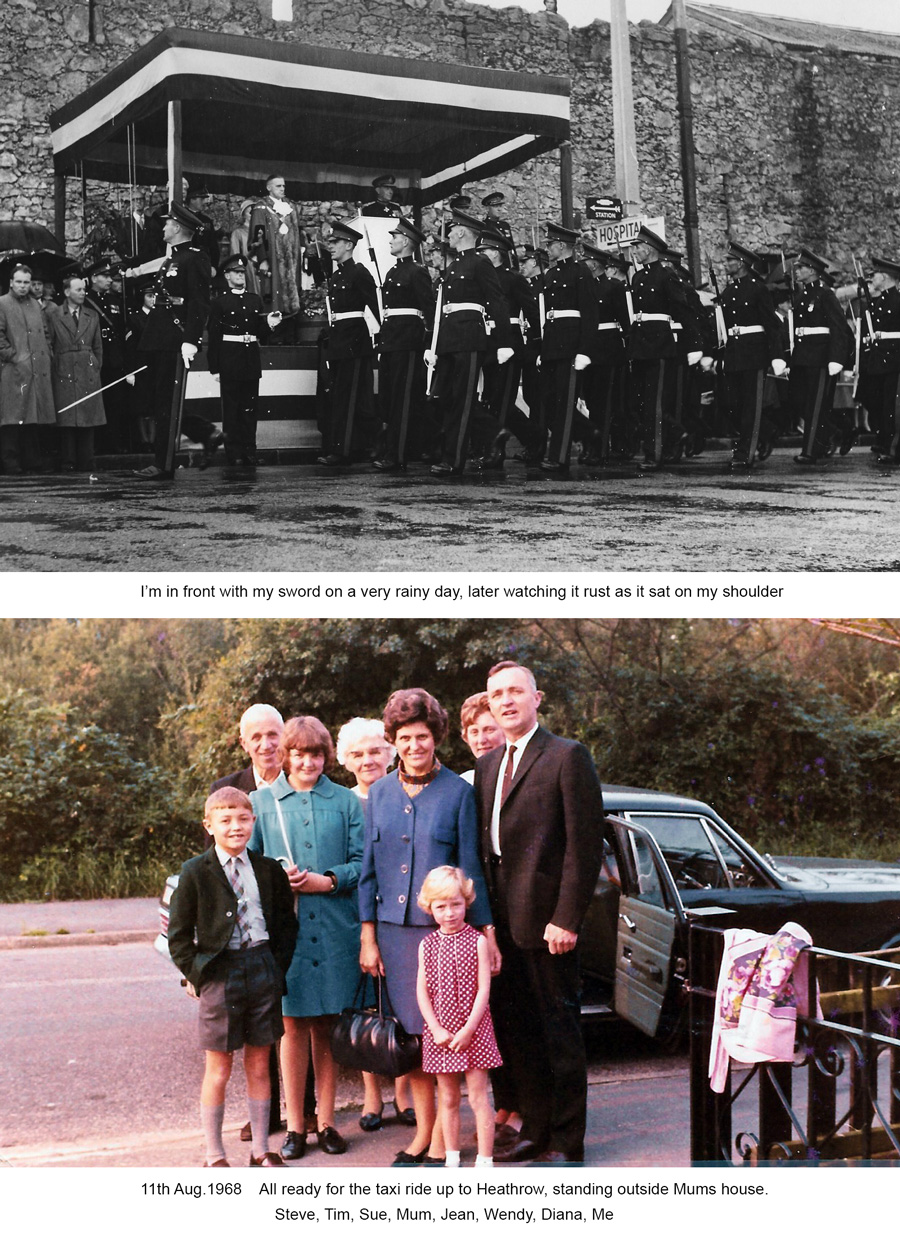

A removal company contracted by Westinghouse arrived and packed all the furnishings in a container and we were off to my mother’s home in New Milton for the last couple of days.

On the 11th of Aug 1968 we took a taxi up to Heathrow and set off on our new adventure.

I had heard stories about the steel mills of Pittsburgh and the desolation, but as we flew in low on our approach to Pittsburgh airport I was astonished to see the beautiful green forests.

Before we left Leicester, I had a letter from a fellow English engineer at Pittsburgh (a John Reeves) who had been delegated to liaise with us and help where he could.

Through him, we had fixed up a rental home in Penn Hills, not far from the labs and he met us at the airport and took us for our fist meal in the USA (huge by our standards) and then to a motel for the night.

Next morning, he picked me up and took me into the laboratories. Showed me around the department and introduced me to the other engineers. They were a diverse lot, some American but a cross section of European and Asian. Quite a number of UK origin.

The next day I met with Mr. Walker and he told me that I would be working directly for him and would not be attached to the other sections. As it turned out, ultimately, I never did work in one of the four sections, though I did get some work from them.

At this point I found out why he was interested in the Magnetic Cross that he had questioned me at the interview. It appeared that a company called Wanlass had approached one of the Westinghouse divisions, called the Specialty Transformer Division to see if they would be interested in making, under license, an ac stabilizing transformer they called a paraformer. A stabilizing transformer that converts a 60 hz ac which can vary by +/- 1%. Essential for some critical loads.

Mr. Walker had contracted with a University of Pittsburgh professor, a Dr Meiksin is examining this paraformer during the summer break. Dr. Meiksin had done a marvelous math electrical analysis and had confirmed that the device was a parameter oscillator which means that a parameter of the device, in this case, the inductance was varied twice each cycle to maintain the oscillation. Mr. Walker had a feeling that it could be duplicated and yet, would bypass the patent. “Have a look”, he said to me.

As the mathematical analysis did not indicate any way of synthesizing the simulation, I went over to the laboratory library, which had a micro film library of all patents and each one exploited a different application such as frequency multiapplication and division and phase shifting.

It didn’t take too long before I realized that none of these four path structures were unique. By bending and stretching the magnetic structure of each application I could convert one to another. Obviously, this was not the way to go.

Then I had my moment, I was looking at the original Magnetic Cross structure and realized that if I folded it, I could make a three-path structure. This was obviously different and what is more, uniquely united to the strip wound cores made by the Specialty Transformer Division. The only question was, will it work. We had a workshop attached to our division and they had winding facilities, a range of different sizes of strip wound cores and copper wire.

I didn’t take long to find a suitable three phase (3 leg) core and to get it wound. Now for the moment of truth.

Imagine my delight when the structure exhibited all the characteristics of the paraformer, i.e. a jump start, switch off on over load and a stabilized output. The only problem was that they all occurred at the wrong points, that didn’t take long to correct by changing winding turns and leg dimensions. Once done, the unit performed just like the paraformer, but better, in that the output always came up with the same 90 degrees lead or lag in the input.

With help from the patent department, I was able to get no less than 4 patents issued, one for the basic device and 3 more for applications using the device.

In Aug 1969 we bought a 2 bedroom house at 3515 Logans Ferry Road in Murrysville about 9 miles from the labs. It came with about 2 ¼ acres of land.

(L – R) Mum Winifred with little David, Richard, Rosemary, Susan, Steve, Jeannie, Me, Barbara, Brian, Diana, Peter

1960 -1969